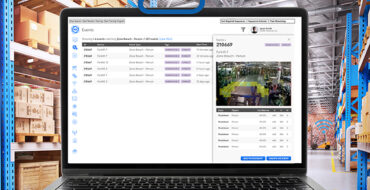

OmniPro Vision AI Forklift Pedestrian Detection System FAQ

These are the common questions people ask about Omnipro, our award-winning warehouse collision avoidance system.

Click on the question you want answered.

• Can OmniPro reduce SIFs (serious injuries and deaths) in our operation?

By giving forklift operators “another set of eyes” and alerting pedestrians, OmniPro can help reduce the likelihood of SIFs

• How does OmniPro detect people and equipment in a forklift operator's blind spots?

In front, OmniPro is affixed to the side of the powered industrial truck (PIT) mast, which gives it a 120-degree view. The rear camera also provides a 120-degree field of view, eliminating potential blind spots.

• Does it slow the machine down?

OmniPro Vision AI can optionally be machine integrated. With integration, power to the throttle is disrupted when zones are breached. OmniPro also offers customers the option of setting up speed zones, in which the PIT is slowed to a customizable speed while in the zone.

• What are zone breaches?

Zones are areas in the PIT’s path of travel that the operation has identified as potentially dangerous. Usually, the zones are yellow (warning) and red (danger). If a person, PIT or object (depending on what the operation has instructed OmniPro to alert on) is detected within any of the zones, a “zone breach” is recorded by the system.

• How is it mounted to the machine?

We use multiple industrial magnets to mount OmniPro on the PIT. Magnets securely attach OmniPro and also make it easier to install and remove.

• Does it affect warranties?

Warranties are not affected because of the magnet mounting. For example, if you install OmniPro on a leased PIT, you are able to remove it without a trace.

• What is the lead time?

A typical pilot lead time is 30 days to get a unit installed, but lead time can vary due to different applications. Everything is designed, manufactured and shipped out of our U.S. facility.

• What is your installation program?

We can dispatch Matrix’s trained technicians or train your staff to do the installation.

• How long does it take to install?

It generally takes an average of four-to-six hours per PIT, depending on options.

• Can OmniPro blur faces?

Yes!

• Does it take video?

No – OmniPro captures images at a rate of two per second and stores images two seconds prior to, during and after a zone breach. (some limitations apply)

• How is the data stored?

The connection is system-specific. We have a stand-alone system that can use Wi-Fi, Bluetooth or Intranet with any laptop or smart phone. We also have a cloud-based option.

• How long is the data stored?

On average, data is stored for a rolling 30 days. On the cloud, storage times vary.

• How does OmniPro minimize nuisance alerts?

The high accuracy of OmniPro’s Visual Artificial Intelligence technology combined with years of Matrix development and fine-tuning have resulted in minimal nuisance alerts for operators.

• Is it cost-effective?

Yes. In addition to the human and emotional toll, the National Safety Council reports that a fatality will cost a company an average of $1.39 million and a medically consulted injury will cost an average of $40,000. OSHA estimates that 35,000 serious injuries and 62,000 non-serious injuries involving forklifts occur annually. OmniPro is a highly cost-effective collision avoidance system for a company wanting to make its operation safer.

• Are you able to detect other PITs?

Yes – OmniPro has been trained to identify forklifts, vehicles, haulers and a full range of wheeled PITs.

• How long has Matrix been in the collision avoidance business?

Matrix has been in the proximity detection business since 2008.

• Will this work on any make or model of PIT?

As a stand-alone system, OmniPro will work on any make or model. Throttle integration is make- and model-specific.

• How many cameras can each system operate?

Four per standard hub. (some limitations apply)

• How many zones does each camera generate?

Each camera can generate up to five zones. Most customers use yellow (warning) and red (alert).

• Does it require a monitor?

A monitor is optional, but an increasing number of operations are opting for them. It can be set up as a split screen or to view the direction of travel.

• Has OmniPro won any technology awards?

OmniPro was recognized with NIOSH’s Mine Safety and Health Technology Innovation Award.

• Can OmniPro detect people in different positions?

OmniPro can identify pedestrians in any posture, including standing sideways, crouching, kneeling and partial view, as well as people wearing PPE.

• Does OmniPro only detect people?

OmniPro also has a library of equipment and key objects on which it can alert. Each operation can select what it wants OmniPro to alert on.

• Can it be adapted to different operating environments?

OmniPro is adaptable to any operating environment. Zones are configurable to a customer’s specific needs using push-and-pin software.

• Can OmniPro handle extreme environments?

OmniPro is rugged and performs very well in extreme heat and cold. Both its hub and cameras are IP67-rated. Current temperature rating is -40° to 50° Celsius.

• How does OmniPro work on narrow aisles?

OmniPro’s zones can be configured based on the width and length of aisles.

• Does OmniPro actively protect workers and equipment, or is it a training tool?

It is both – OmniPro not only provides multiple alerts for operators, it also helps them become more aware of their environment and hazards.

• What size is OmniPro – will it take away from our driver’s field of view?

OmniPro is a compact 5” tall by 2.75” wide by 1.76” deep. Its small size causes minimal impact to a driver’s field of view.

• Can OmniPro identify our safest/least safe drivers and our most hazardous areas and times of day?

Yes – OmniPro gives operations the ability rate drivers, areas and time of the day.

• Does it have a mast height sensor?

OmniPro Vision AI has an optional mast height sensor that takes power away from the throttle whenever the mast is at a certain height.

Seeing is Believing – Ask for a Demo!

MATRIX