HIGH-SPEED GIGABIT MODULAR NETWORK

Q&A / Case Studies

Matrix N-Connex Q&A

We’ve found that people have a hard time believing N-Connex can really do all it says it can – and at the lowest cost per mile. Here are some of the questions frequently asked by potential customers:

Who can use N-Connex?

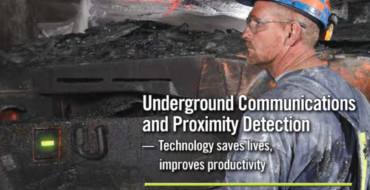

N-Connex high-speed network is best suited for hardrock mines, coal mines (outby), tunnels and industrial facilities.

Is it possible to add a Wi-Fi system to our mine?

Yes, N-Connex can be deployed into mines with no network infrastructure as well as incorporated into existing infrastructure.

The Distribution Module* is the core N-Connex component that delivers a highly reliable, gigabit Ethernet network. When combined with the N-Connex Bolt Access Points, the system can achieve strong and reliable Wi-Fi coverage in mines, tunnels and industrial facilities. Remember, N-Connex is modular, so you only invest in what you need, then add as you grow.

*The Distribution Module includes eight (8) managed PoE ports, two (2) Non-PoE Ports and four (4) Single-Mode Fiber Ports to enable a range of solutions and network topologies.

What will Wi-Fi allow us to do?

Communications

The number one application mines are looking for is clear, reliable communications. N-Connex, combined with Icom’s VoIP handsets, provide crystal clear communications with the option of virtually unlimited call groups and directory. When connected to the surface PBX phone system, the Icom radios deployed underground can call off-site using preprogrammed numbers. N-Connex additionally offers a vehicle-mounted version of the Icom IP100H handset.

The Icom IP100H handsets also have a “Lone Worker” feature that allows the system to be preprogrammed to “beep” a specific radio, or group of radios, every x number of minutes. If the operator doesn’t “click” their mic to acknowledge the system “beep,” an alarm can be triggered.

Smart phones additionally can be configured to work on the network. N-Connex supports any standard Wi-Fi device, such as IP phones, smart phones, IP radios, laptops and tags. Network access can be provided underground, allowing system checks and reports to be input directly onto the network.

We can also enable smart phones to make Wi-Fi calls. Important to note; smart phones, tablets and computers connected to the network can have functionality limited to avoid abuse. We can limit/restrict those devices able to connect to the system by either implementing a password or limiting specific IP/MAC addresses.

Tracking

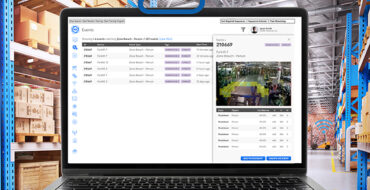

The number two application mines are looking for is tracking. N-Connex, when combined with NLT’s Digital Mine (DM) and Wi-Fi tracking tags, can provide real-time tracking of personnel, vehicles and assets both in and out of the mine. DM allows management to remotely monitor activity in the mine, including knowing who and when personnel enter/exit the mine as well as where all personnel are at all times. The tracking feature can help the mine save significant time deploying the right person, such as an electrician, to an area of interest. It also helps mine management know where equipment and assets are, when needed. DM’s history can save activity data for up to 366 days. Anything with a MAC address can be tracked over the network, including smart phones, tablets and computers.

Areas of concern, such as shops/stores/dangerous areas can also have a zone set up around them called “geofencing,” which provides an alert if any unauthorized personnel enter the zone.

DM’s tracking module can also be used to monitor production within the mine. By setting up “Wi-Fi Gates” at pick-up and dump points, haul truck cycle times can be monitored in real-time. Monitoring vehicle activity can dramatically modify behavior, resulting in increased productivity.

Environmental Monitoring

The third application is environmental monitoring: gases, airflow, temp/humidity, as well as strata movement. Monitoring stations can either be hardwired into an N-Connex switch, Edge or Distribution Module, or they can be connected to the network wirelessly.

Should a preset threshold that is set in DM’s Environmental Module be exceeded, a local or mine-wide notification can be triggered utilizing the N-Connex Alarm Module. Email alerts can also be automatically sent out to a mailing list.

Vehicle Performance/Health Monitoring

The forth application is vehicle performance/health monitoring. KPI’s of the engine, as well as tire pressure and vehicle speed can be monitored remotely. This allows management to monitor abuse as well as plan preventative maintenance.

Cameras

The fifth application is the support of IP POE surveillance cameras. Matrix provides a full complement of fixed lens, Pan Tilt Zoom (PTZ), infrared and Wi-Fi cameras. Cameras are controlled and monitored using a Video Controller, available in 32, 64 and 128 camera configurations. Recording memory is customizable based on the applications requirements. With VPN access, the Video Controller can be monitored on any device, anywhere there is network connectivity.

How does this system differ from RF communications?

RF systems such as Leaky Feeder or low-frequency solutions like IWT are functional for communications and have some tracking capabilities, but due to their low bandwidth, they have little-to-no data capabilities. Wi-Fi will provide you with standard telephone-like communications along with Internet access and email. RF will handle some of today’s needs but does not offer future-focused solutions. For example, with N-Connex, you can remote in, obtain near real-time analytics from vehicles and have higher-level reaction data in the event of an emergency.

Traditional RF systems deployed on the surface also need a license to operate. Wi-Fi operates on an open bandwidth, so no license fees apply.

If I’m travelling, can I contact people at the work site remotely?

You can monitor activities in the mine by logging into DM using any device: smart phone, tablet or computer. The screen auto-scales to screen size/dimensions.

Do we have to buy the entire system up front?

N-Connex is modular, which means that you can start with the basic Distribution, Edge, Bolt and Power Modules. When you are ready, you can expand the base or add additional modules, such Control and Alarm, or additional features, like Battery Backup. New modules are continually being added due to the unique design that supports third-party electronics and hardware. N-Connex Network Extenders overcome the inherent 100M CAT6 Ethernet cable distance limitation and can be added as your coverage needs grow. (See Build-as-You-Go Scenario.)

Matrix can work with a mine to provide a solution to match any budget. An entry-level budget solution might only provide Wi-Fi hotspots at power centers and/or the populated areas in a mine, like the working face. A basic tracking solution could monitor the mine’s portals and then Wi-Fi gates could be established at key areas in the mine and zones established to give a basic understanding of who and what is where in the mine. For either scenario, additional network infrastructure can be added as funds become available to add Wi-Fi coverage and tracking granularity.

Will this system nickel-and-dime us?

There is no licensing fee for the technology, no annual fee for the base system and no license fee per user. Once you buy it, it’s yours.

We do encourage mines to purchase a maintenance package that can range from remote network monitoring to phone support, as well as regular site visits. The annual maintenance fee is 20% of the cost of the software modules. This pays for all system updates and most upgrades to the system. Optional major upgrades might require an additional fee. A maintenance package will ensure that best practices are adhered to, providing the best possible experience from the system.

Will this high-speed network break our budget?

N-Connex has the lowest cost per mile of any high-speed network for mines, tunnels and industrial facilities on the market today. Our modular network provides for a basic up-front cost and the ability to budget for expansion, all at a high value-to-cost ratio. Leasing options are also available.

Do we need to hire specially trained personnel to program and maintain the system?

The system has been designed to be installed and supported by personnel with basic training. No specialized skills/training required.

The system comes pre-programmed and can be easily maintained with existing staff. N-Connex features allow semi-skilled people to provide rapid first-line support for your network.

At the beginning of an installation, Matrix integration personnel will provide mine employees with hands-on training, including how and where to install the equipment. This usually lasts between 2-3 days. Once the infrastructure has been installed, Matrix’s integration personnel will return to the mine for final commissioning and user training. Final commissioning can take between 2-3 days.

How does a modular system work?

N-Connex modules simply “plug & play” using Power Over Ethernet (PoE) and pre-terminated CAT6 Ethernet and fiber cables. N-Connex’s CAT6 Network Extenders and Fiber Joiners are easy to use and eliminate the need to terminate or splice in harsh environments. These devices ensure N-Connex networks can cover large mines, long tunnels or extensive industrial facilities. Should a module ever need repair, it can be easily replaced by a back-up module, which minimizes network downtime.

Initially, Matrix integration personnel work with mine management to establish network coverage in the mine. Once that’s established, a detailed mine map showing equipment locations and cable runs is provided.

Is it rugged enough for the harsh operating environment in our operation?

N-Connex has been specifically designed to withstand harsh environments and extreme treatment. The systems are in operation in some of the harshest conditions imaginable.

All components of the N-Connex system are IP67 rated, meaning that they can be submerged in 3 feet of water for 1 hour. The components can also withstand impact onto concrete from 3 feet (though not advised).

Is MSHA going to require tracking in all mines?

There is no word yet, but the general consensus indicates that it most likely will be required in the near future. Either way, tracking of personnel and equipment is a good idea for the mine. Tracking is a proven management and safety tool. If there’s an accident, there’s an automatic snapshot of where everyone is in the mine, which helps direct efforts. Tracking personnel has also proven to make miners more productive and efficient.

N-Connex’s Bolt Wi-Fi Access Points come tracking ready. All you need to introduce tracking into the mine is the Digital Mine software/server. Any device on the network with a MAC address can then be tracked. Personnel tags, vehicle tags and cap lamps with tracking tags installed can also be deployed on the network.

How can tracking benefit our mine?

Among other things, tracking can provide valuable insight into employee behavior as well as locations of “choke points” or inefficiencies in the mine’s current processes. During a mine emergency, it can pinpoint locations of all personnel and vehicles.

The DM Tracking Module allows management to monitor who and when personnel and guests enter and leave a mine. This can be used for HR/Payroll as well as security. Knowing instantly where skilled personnel, such as electricians, are in the mine can save significant downtime deploying the right person in the event of an issue.

Can N-Connex handle control and automation of equipment, such as Tele-Ops and Autonomous Vehicles?

N-Connex has been extensively tested and exceeds minimum standards for latency and handover time.

North American Palladium is currently remotely operating a Sandvik scoop on an N-Connex network. We had an opportunity to speak with the Sandvik install engineer, and he told us that he’d never deployed a teleremote system as easily. The second day on site they turned everything on and “it just worked. That never happens!”

What solutions can N-Connex provide for tunneling projects?

N-Connex is the perfect solution for tunneling. Tunnels are dynamic environments usually populated by many contract workers. As a result, equipment and cables are easily and often damaged. N-Connex’s modular design and pre-terminated cables allow for advancement of the network and repair of damaged equipment to be done quickly and easily with little-to-no training.

Matrix’s Digital Mine Tracking can also keep track of contractors entering and exiting job sites. This solution allows HR to accurately monitor payroll, a problem for large active sites. Tunnels are often built out from various points simultaneously. By connecting the N-Connex networks for the internet, personnel at the various construction sites can communicate. Management personnel located at a remote field office can also communicate with and monitor activity on site.

Tunnels are often wet environments. The N-Connex components have been designed to keep input ports protected if placed on the ground. The IP67 rating of all N-Connex components and cables protects them even under the worst conditions.

NLT has been awarded some of the largest and most prestigious tunneling projects in the world including:

- Crosslinx – Eglington Subway Extension in Toronto is the largest tunneling project in Canada. N-Connex is being used to provide communications at 3 underground stations simultaneously.

- Brennor Base Tunnel – Austria. At 34 miles, it is the largest rail tunnel project in the world. Everyone in the industry, including two large Austrian firms, were bidding for the job. N-Connex’s versatile, reliable and cost-effective system won out.

What companies are currently using N-Connex?

Companies that have chosen N-Connex for their network solutions for mining include: Burning Springs Mine, Glencore Kidd, North American Palladium, Pan American Silver, Codelco Andina Mine, Volcan Chungar Mine and Minas de Bacis. Tunneling projects that have utilized N-Connex systems include: Forrestfield Airport Link, Amaroo Sewer Tunnel, Brisbane N-S Bypass Tunnel, Ottawa Lite Rapid Transit Line tunnel, Sydney North West Rail Link, Crosslinx Subway Extension Toronto and Brennor Base Rail Tunnel Austria.

Build-as-You-Go Scenario:

In 2019, you buy the basic N-Connex backbone that provides Wi-Fi and Internet access to the mine. In 2020, a future regulation is announced about tracking. Now you can add the Tracking Server, Devices and Tags. The following year, you’re ready to add Machine Telemetry. In 2022, you want to add Tele-Ops and Autonomous Mining. No problem. You already have the bandwidth and everything you need to build onto your basic system. By 2023, it’s time to expand into another zone. With the modular system and extenders, N-Connex readily provides coverage for the new areas.

___________________________________________________

Case Study Briefs

Mining, tunneling and industrial companies around the world have selected N-Connex for their hi-speed network needs. The following provides a partial list of those utilizing N-Connex as well as brief case studies summarizing their projects.

Companies Currently Using N-Connex:

Companies that have chosen N-Connex for their network solutions for mining include: Burning Springs Mine, Glencore Kidd, North American Palladium, Pan American Silver, Codelco Andina Mine, Volcan Chungar Mine and Minas de Bacis. Tunneling projects that have utilized N-Connex systems include: Forrestfield Airport Link, Amaroo Sewer Tunnel, Brisbane N-S Bypass Tunnel, Ottawa Lite Rapid Transit Line tunnel, Sydney North West Rail Link, Crosslinx Subway Extension Toronto and Brennor Base Rail Tunnel Austria.

Case Study Briefs:

The following project snapshots are based on current installations:

Communications, Tracking and Cameras in Burning Spring’s Aggregate Mine – digital communications replaced an outdated leaky feeder system, establishing communications throughout the entire mine that the mine foreman describes as a “100% difference.” They have installed cameras that management sees as a way to drive cost savings, such as identifying chute back-ups and saving belts as well as tracking, which plays a key role in the mine’s emergency plan. Operators can now talk directly to maintenance, saving up to 45 minutes per incident when a breakdown occurs. Management can now look on a screen to see where all their workers and equipment are located on the surface and underground.

Wi-Fi Coverage and Communications to Link Two Silver Mining Operations – the project included supplying of all hardware and services to enable Wi-Fi communications throughout the underground tunneling development and mine’s surface, primarily linking a new underground mine with an existing and operating VHF communication system.

Major Extension of Underground Network in Zinc and Copper Mines – a low-cost and easy-to-install extension of the mines’ Cisco Wireless infrastructure to over 40 locations was accomplished through the N-Connex Edge, Ethernet Extenders and pre-terminated CAT6 cable to provide network connectivity.

Tracking, Logging and Visualization of Haul Track Activity in a Hard Rock Mine – a forward-thinking mining company chose N-Connex for location tracking, logging and visualization of haul truck activity. As a result of monitoring vehicle downtime during shift changes, productivity improved by an average of 1.5 additional cycles per vehicle, per shift, and after gaining insight into operational bottlenecks, productivity improved by an additional load per truck, per shift, increasing overall output by an average of 50 truck loads per day.

Development of Innovation Center Featuring Tracking, Monitoring and Emergency Management (and Preparation for Tele-Ops and Mine Automation) in Palladium Mine – Phase 1 featured Vehicle Tracking and provided valuable insight into employee behavior and “choke points” in the mine. Phase 2 involved applying N-Connex technology to expand Wi-Fi, Tracking and Gas/Airflow Monitoring as well as add Emergency Evacuation modules and Data Screens. Future-focused Phase 3 will allow Tele-Operations and Mine Automation.

Control and Monitoring of Paste-Fill Operations in a Zinc Mine – the N-Connex solution allows the mine to remotely monitor and control paste-fill operations underground on six levels. The system enables underground Sensors and IP Camera signals to be observed anywhere on the network and real-time management of both surface and underground control equipment.

Airport Link Tunnel Emergency Systems – N-Connex provided a network-based system for alarms and emergency communications that were designed to offer communication redundancy, Wi-Fi coverage and tracking for more than 400 personnel and vehicles.

MATRIX