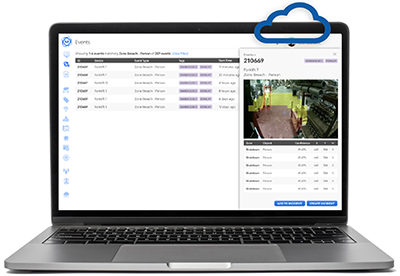

“With OmniPro’s new data-rich cloud application, facilities can tap into the latest technology to improve safety.”

Real-Time Data and A.I.:

How Collision Avoidance Taps New Tech

to Boost Facility Safety

Data—it’s a word that resonates in today’s world. With information flowing from every corner, we find ourselves surrounded by countless data points: think about how many times an operator starts and stops a fork truck and how often a fan in the facility turns on and off. The availability of data seems endless. However, amidst this abundance lies a challenge that many of us face—how do we sift through this data overload, avoiding paralysis and inaction, to decipher useful information?

Real-Time Data Can Drive Actionable Insights

What does actionable data look like and how can we collect it? Focusing on collision avoidance, we can start by identifying zone breaches around a piece of equipment, which happen when an operating vehicle gets too close someone or something. We can also consider breaches found in stationary applications like intersections.

With zone breaches, the initial step is getting the necessary information. Vision-based A.I. collision avoidance technology provides knowledge of the incidents occurring, and its camera system offers the added benefit of having photos of the incidents that can tell a story. These photos aren’t biased, emotional or open to interpretation—they provide a true picture of what’s occurring.

As we start to leverage the available data, we can begin to move toward actionable insights, such as:

- at this intersection at this time of day, the data sees a higher number of interactions;

- we have four different brands or types of lifts in my facility, and the data is showing significantly more incidents on this type or brand of machine in a specified area of the operation;

- there are more close calls in one area than any other place.

These data points also have the ability to drive near-miss initiatives, providing a huge opportunity to prevent accidents, injuries and material damage and helping movement toward a safer operation.

Visual Artificial Intelligence – Data + Photo Documentation

In simple terms, vision-based A.I. involves taking thousands and thousands of photos of an object or group of objects we want to detect and training a model on those photos. A machine learning algorithm then determines, based on the objects you’ve taught it, a confidence level for any object it identifies in a new frame or photo that is presented. By continuing to do this with new objects, an object library is built, and this library allows operations to decide, in the case of collision avoidance, what types of objects on which to alert.

During the past five years, Matrix has been dedicated to updating and refining the model, minimizing false alerts and optimizing processing speed. We also have an entire analytics team that thrives on determining how to filter or decipher the actionable data.

OmniPro Collision Avoidance System Taps the Best of Real-Time Data and A.I.

Through this research and work, Matrix has been able to develop the innovative OmniPro collision avoidance system. OmniPro enables line-of-travel, crosswalk and blind-spot pedestrian and vehicle alerting for mobile equipment. This award-winning* system, which works without personal wearable devices or tags, not only “sees” and identifies people and hazards, alerting with visual and/or audible alerts, it also photographs and reports on zone breaches.

With OmniPro’s new data-rich cloud application, facilities can tap into the latest technology to improve safety. For example, when management has access to detailed collision avoidance data and photos showing what is happening in the facility in real-time, they can take effective action that allows the mobile equipment operator, pedestrians and the facility to be as safe as possible. Using this innovative application of Visual Artificial Intelligence, the OmniPro collision avoidance system gives warehouses, distribution centers and manufacturing plants the ability to log and analyze a wide range of data related to zone breach notifications. This information can provide critical insights about hazardous areas and ultimately serve as a basis for improving facility safety, including adjusting workflows, improving layouts and identifying the need for additional training.

For example, using OmniPro data, operations can answer many questions, including:

- How many close calls/near misses have occurred today?

- Who are your best operators/worst operators?

- What types of machines are having the most accidents?

- Where are incidents occurring, and are there hot spots in the operation?

The system provides this and other information to help upgrade facility safety. Additionally, OmniPro’s customizable solution can be adapted to match any operating environment through its programmable field-of-view zone grid configuration tool, which enables it to meet the safety requirements of different operations.

To learn more about the OmniPro collision avoidance system, visit www.matrixteam.com/omnipro

*OmniPro received the 2020 U.S. National Institute for Occupational Health & Safety (NIOSH) Mine Safety and Health Technology Innovations Award.

Check out this additional forklift safety blog piece by Matrix:

Blog – New or Fatigued Workers Can Raise Accident Rates