YOU CAN’T MANAGE

WHAT YOU CAN’T MEASURE!

Telematic Engine Performance Data Collection and

Real-World Analysis for Better Decision Making

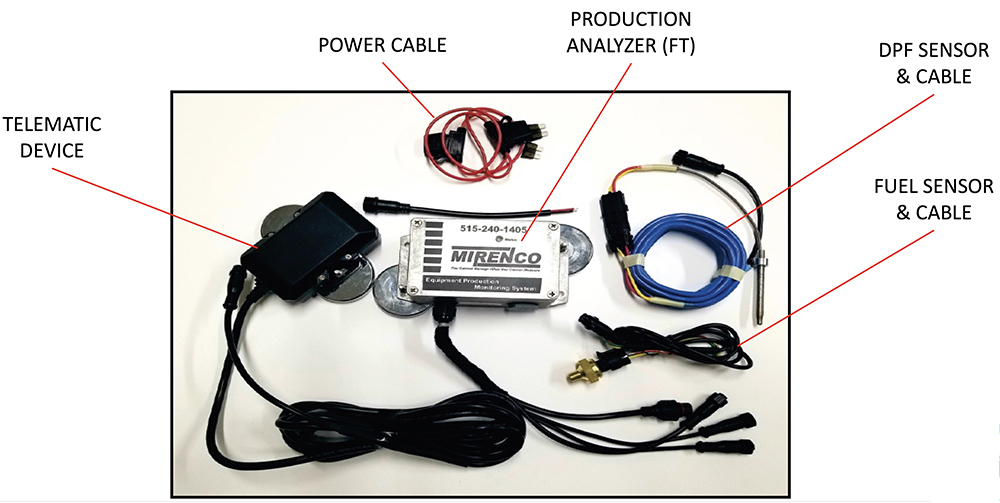

Magnet mounting simplifies installation on the exterior of the

vehicle or can be hard-mounted in a protected location

Mirenco and Matrix can help lower the cost of your overall fleet maintenance costs by giving you the data and analysis you need to make the right decisions!

Founded in 1997, Mirenco’s core business is gathering and reporting accurate, real-world engine performance data that helps companies monitor DPF for fuel savings, experience lower downtime, prevent costly repairs and operate more productively.

- Provides a simple solution for the burden of on-site fleet monitoring by monitoring vehicles at single or multiple job sites

- Patented telemetry sensors for remote location reporting and engine performance analysis

- Engine performance / status reporting and database maintenance

- Real-time problems are identified before expensive breakdowns happen

- Sensor system fits all makes and models of heavy equipment

- Currently monitoring engine performance for 31 mining companies at 136 sites

DATA / MONITORING PRODUCTS

- Equiment Production Monitoring System (EPROMS)

- Fuel Tracker

- DPF Regeneration Monitoring

- Mirenco Diesel Evaluation Program (MDEP)

- Universal Air Filter Monitor (UAFM)

MIRENCO PRODUCTS & SERVICES

EQUIPMENT PRODUCTION MONITORING SYSTEM (EPROMS)

EPROMS provides operators with an early warning of Diesel Particulate Filter (DPF) problems

- Help reduce DPF replacement costs

- Eliminate combustion and performance loss

- Reduce the frequency of cleaning/replacing the DPF element

FEATURES

- All hardware and necessary cables are included

- Telematic device sends sensor information and location (GPS) data

- Magnet mounting simplifies installation on the exterior of the machine or can be hard-mounted in a protected location

- Production Analyzer sends information through the telematic device

- Energy usage as a percentage of Horsepower for productive and idle time

- Fuel use per second, minute, hour, day, week, month and year

for productive work and idle time

EPROMS can be installed by a Mirenco or Matrix technician.

The unit can be moved to another vehicle

when the monitored vehicle

is retired or sold.

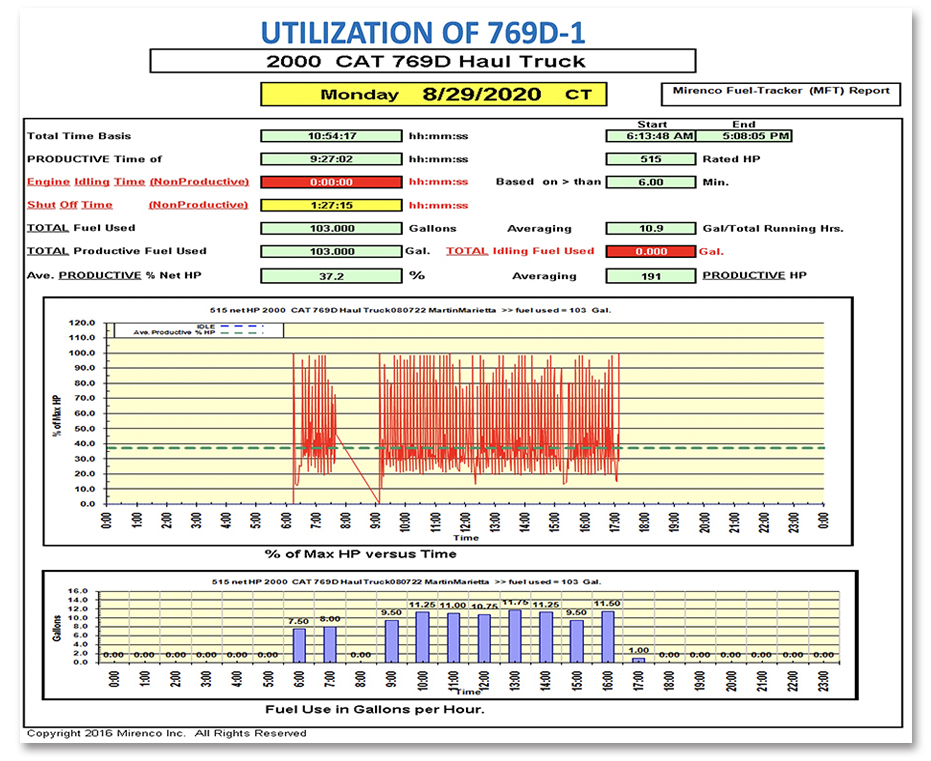

FUEL TRACKER

The Mirenco Fuel Tracker provides a comprehensive profile for each assigned vehicle. This program works on ALL turbo-charged diesel engines from ALL manufacturers.

The base report focuses on units of fuel burned per hour. Fuel use is correlated to turbo boost pressure which makes this report reliable and accurate / predictable.

WHAT IT TRACKS

- Productive work time

- Non-Productive work time – reports exact idle time – not based on key-on / key-off activity. Reports exact shut-off time.

- Determines Power Train Load

- Fuel usage by GPS-tracked vehicle

- Can monitor air filter, coolant and turbo-performance

REPORTS

- Daily, monthly and yearly

- Productive, idle and shutdown time

- Total, productive and idle fuel use

Fuel Tracker gathers data and provides a comprehensive profile of each monitored vehicle’s performance. It also allows you to do comparison reports on similar equipement.

DPF REGENERATION MONITORING

OVERVIEW

- Monitors the DPF Regeneration process, including:

- Length of the Regenerations

- Number of DPF regenerations per day

- Gallons of engine diesel fuel per hour of DPF Regeneration

- Thermocouple installed at DPF exhaust outlet

A high number of DPF Regenerations means something is

going wrong with your engine. Downtime is coming soon.

PROACTIVE fleet operators use MDEP to control their DPM levels

REACTIVE fleet operators wait until OSHA issues citations

MIRENCO DIESEL EVALUATION PROGRAM

OVERVIEW:

- On-site exhaust testing

- Five gas analysis test

- Wireless handheld

- Smoke meter for DPMs

- Acceleration Snap Test (DPM)

ACCERATION SNAP TEST (DPM)

High DPMs = Over-Fueling = Black Smoke = High Emissions = WASTED FUEL

DPM RATINGS

0 – 20% = Acceptable DPMS

20 – 30% = Combustion Issue May Exist

30% & Up = Combustion Issue Causing Fuel Loss

NOTE: 5% DPM = 1% Fuel Loss

FIVE GAS ANALYSIS

Hydrocarbons (HC) represent unburned fuel. Good running engines show HC levels of

10 ppm or less.

Fully burned fuel shows up as CO2. Higher numbers indicate greater engine efficiency, while lower numbers indicate the opposite.

CO represents partially burned fuel. High CO readings indicate incomplete combustion.

O2 is unburned oxygen. O2 readings indicate the amount of combustion and engine load.

NOx represents the products of burning Nitrogen. NOX will increase with higher combustion temperatures.

WHAT CAN MDEP TELL YOU ABOUT YOUR ENGINE?

– Air Restrictions

– Injector Timing

– Air / Fuel Ratio

– Turbocharger Problems

– Valve Lash

– Faulty Injectors

– Faulty ECM Flash Files

WHY DPM MANAGEMENT IS IMPORTANT TO YOUR MINING OPERATION

Diesel Particulate Matter (DPM)?

DPM is a component of diesel exhaust (DE) that includes soot particles made up primarily of carbon, ash, metallic abrasion particles, sulfates and silicates.

Health Effects of DE/DPM?

Short-term exposure to high concentrations of DE/DPM can cause headache, dizziness, and irritation of the eye, nose and throat severe enough to distract or disable miners and other workers. Prolonged DE/DPM exposure can increase the risk of cardiovascular, cardiopulmonary and respiratory disease and lung cancer.

How Can DPM Be Mitigated?

Performing routine preventive maintenance of diesel engines to minimize emissions. MDEP monitors engine DPM levels and allows you to avoid excess levels.

PROACTIVE fleet operators use MDEP to control their DPM levels

REACTIVE fleet operators wait until OSHA issues citations

UNIVERSAL AIR FILTER MONITOR

(UAFM)

FEATURES:

- Early warning of air filter restrictions

- Helps reduce air filter replacement costs

- Eliminates combustion and performance loss

due to air starvation - Can potentially save a possible engine replacement

- Flashing LED light is visible to operator and nearby personnel

- Can be configured to transmit an alert

- Lifetime warranty – can be transferred from machine-to-machine

- Magnet mounting simplifies installation on the exterior of the machine or can be hard-mounted in a protected location

7” x 4” x 2.5”

Includes all Hardware

(Hose, Cable and Brass Fittings)